We offer our customers the following services:

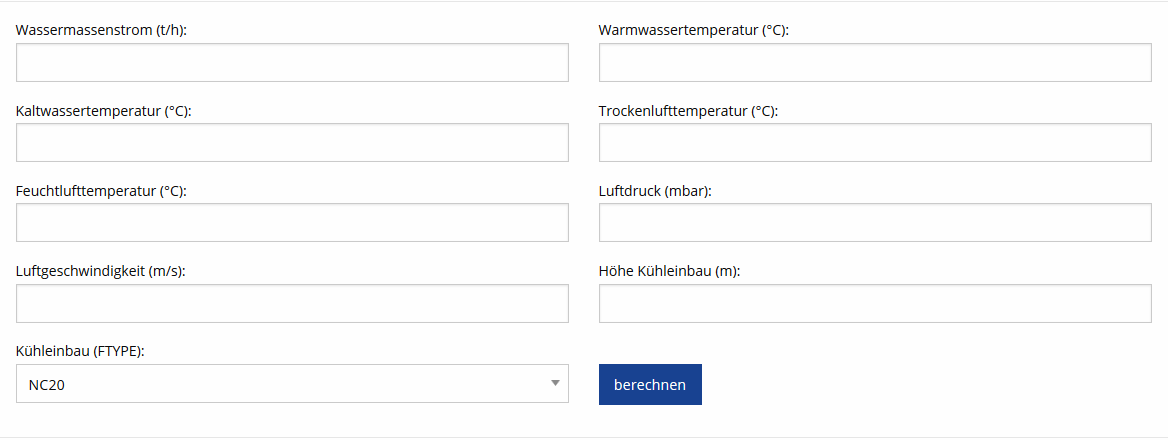

- Free use of our design software (with access code) for cooling tower designs

- Personal support in the design and selection of cooling tower fills

- Design and selection of components in trickling filters applications, e.g. water treatment plants

- Design and selection of plastic components required to operate your system safely

- Project planning and timely execution

- Installation and removal of filling material in water treatment plants

- New development, re-design of custom-made plastic fills

- Transportation

- Use of internal machine and tool construction

- Injection mould construction

- Extrusion die mould

- Worldwide rental of proven Hewitech machines for 'assembly' of films and grid mats (e.g. for large-scale projects or construction sites, optimization of transport costs)

- Delivery of project-specific special components (e.g. substructure, water distribution systems, etc.)

Personal support

We would be pleased to offer you our special services for your specific project requests through our many years of know-how and expertise from the respective sectors. For this purpose, a well-coordinated and highly qualified team is at your disposal, which will gladly take on your problem and work out the best solution for you. This can range from the right selection of plastic components for your application to the “all-in-one" solution for the removal or installation of fills on construction sites.

We are also happy to assist you in the use of our rental machines for the production of fills in your factory or at an international destination of your project. In addition to the correct operation, we make sure that the required quality of the products manufactured is adhered to. Furthermore, the necessary maintenance and care instructions that are of great importance for permanent use and a smooth production process are conveyed on site.

In the event of the welding system registering an unexpected malfunction, we can quickly offer worldwide assistance or remote maintenance free of charge via the "online" interface - to ensure of a timely production execution at your construction site. The machines have been continuously developed within the company group for over 20 years: Customers can always rely on the experience and competence of our staff.

Customized tools

Choosing the right plastic installation for your application is very important for the high performance requirements of your system. Therefore we offer our cooling tower customers the free cooling tower design software, which you can use on our website after registration. This gives you valuable information for choosing the right cooling tower fills. Furthermore, our team is naturally at your disposal.

For all other applications, please contact us directly, so that we can assist you in your selection.

Thanks to our own machine and tool construction, we can customize a customer design flexibly and quickly.

However, this requires close cooperation with our engineers, who can pay particular attention to the necessary details of the microstructure or the technical refinements of the moulding tools. Due to the diverse production possibilities, we can make almost any customer-specific tool design and quickly present the samples. Only after your final approval can production of the customer-specific designed tool commence using our production lines. Obviously, these exclusive products are available solely for you.

![[Translate to English:] Hewitech Assembly Machine](https://www.hewitech.de/fileadmin/co_system/default/media/Editorial/service/Hewitech-automatical-assembly-machine_zugeschnitten.jpg)