lamella settlers

Sedimentation with lamella settlers

Inclined lamella settler are a state of the art technology in water and wastewater treatment. The Technology is used in a vast variety of sedimentation processes

Proven technology

The operating principle of lamella settler is based on a reduced particle settling path.

The related laws of sedimentation have been defined by Allan Hazen in 1904

Numerous applications

Potable water treatment, Industrial-rapid-settling, Primary settlers, Secondary settlers, storm water treatment

Reduced Tank size

The required tank size is significantly less compared to conventional settlers

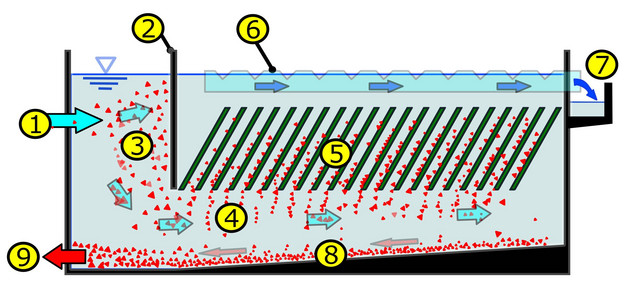

Functional zones of a lamella settling tank

Lamella settlers are build in a variety of configurations. Different functional zones can be identified in typical lamella settling tanks.

The Inlet flow (1) runs against a buffer wall (2).

Energy gets dissipated in the inlet area(3). Subsequently the flow continues to the underflow section (4) where it is evenly distributed to the lamella tubes (5)

Particles collect on the lower lamella plane and collectively slide down due to the inclination.

Clarified water leaves the tube-settler on the upper side and gets collected in an effluent drain (6) that reaches outside the tank where the effluent falls into the collection channel (7).

The particle loaded sludge (8) collects on the tank floor and moves towards the sludge pump (9) with the help of a scraper system.

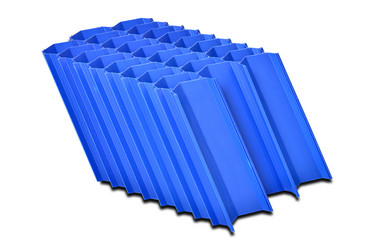

HEWiTUBE – with equidistant chevron

The HEWiTUBE Lamella ´system consists of individual profiles with a tongue and groove system

Self supporting

The modules are rigid and self-supporting , hence it can placed directly on a support structure

Variable Module sizes

HEWiTUBE modules can be produced in almost any size depending on the project requirements

Optimized separation

The settling performance follows Hazens law thanks to the equidistant settling planes

Optimized Sludge movement

The settled sludge moves to the Chevron center line and allows the individual particles to slide down as a dense particle flow

Certified for use in potable water

The HEWiTUBE blue series is certified in accordance to KTW/W270 (German standard) and NSF (US-standard)

Simple on-site assembly

Modules can be assemble on site on a special assembly table

HEWiTUBE lamella modules

HEWiTUBE LS 50 is used for following applications:

Potable water treatment

Separation of flocculated particles from surface water sources

Humus tanks after trickling filter or submerged beds

Separation of biological flocs with low sludge volume

Storm water treatment

For the reduction of the surface overflow rate in small tanks

Industry

Separation of mineral particles and flocculated particles in process water treatment

| Technical data: HEWiTUBE LS84 |

| Specific settling surface (60°): 6,5 m2/m3 |

| Lamella pitch: 80mm |

| Material: Polypropylene |

HEWiTUBE LS84 is used in applications with larger particles and higher sludge volume

Primary treatment

Fort he increased performance of primary settling tanks

Secundary sedimentation

For activated sludge up to ~ 2500 mg/l MLSS and SVI < 120 mg/l

Combined sewer outlet

Installation into tanks prior to outlets

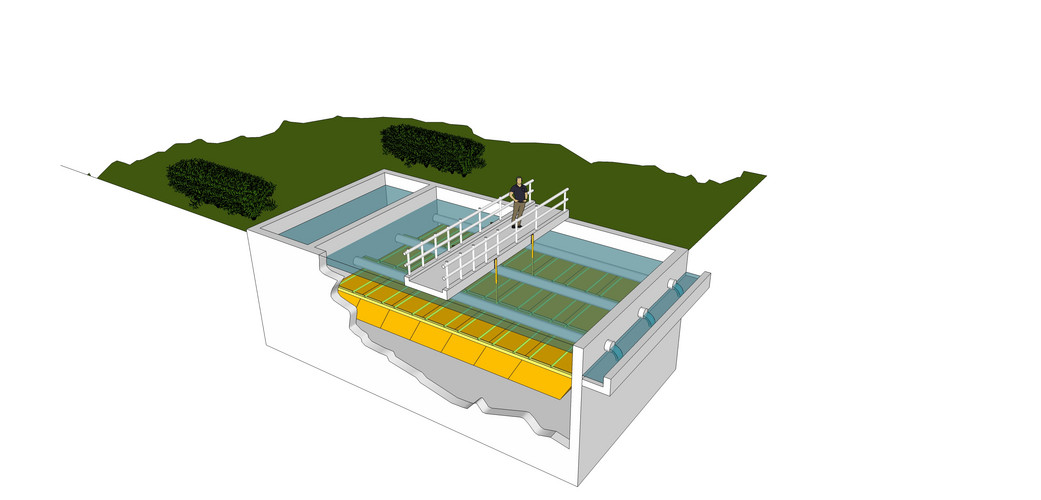

HEWiTUBE tank integration

Installation into rectangular tanks

A rectangular shape is a perfect precondition for the installation, since the surface can be completely utilized

The modules can be placed upon a support structure below the modules, or the modules are connected to a support structure at the upper module level

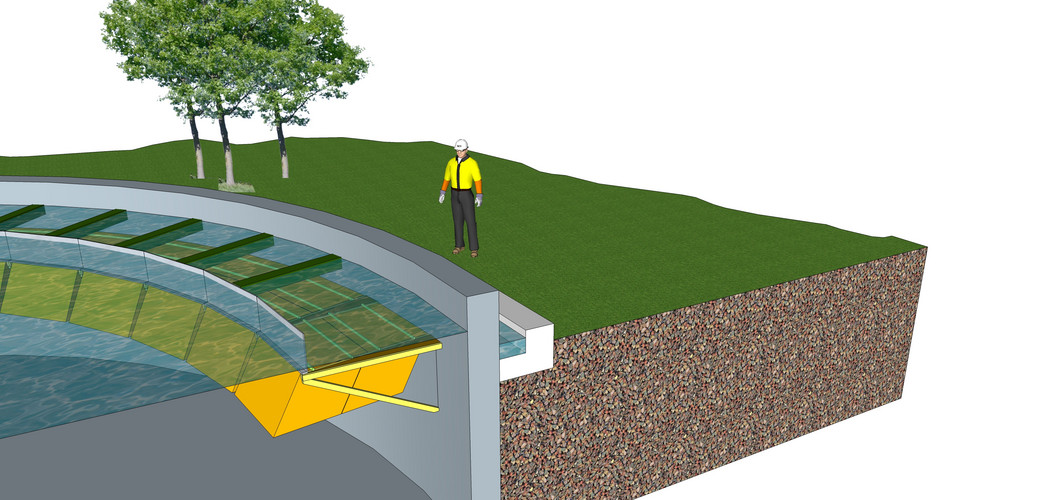

Installation into round tanks

The performance of larger round tanks can be drastically increased by ring section of HEWiTUBE modules along the perimeter..

The modules are hang into wall consoles. Buffer wall segments and effluent launders are connected to wall consoles as well

The design of HEWiTUBE lamellas requires a hydraulic calculation and a support structure design.

Hydraulic calculation

We offer a complimentary hydraulic design based on Hazens laws in order to determine the required lamella volume.

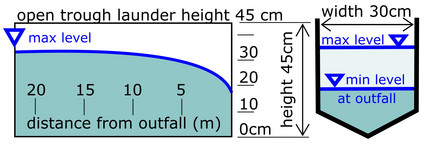

If required we offer a design study for effluent launders as open through with V-notch weirs or as submerged effluent pipe

![[Translate to English:] Unten liegende Haltekonstruktion [Translate to English:] Unten liegende Haltekonstruktion](https://www.hewitech.de/fileadmin/co_system/default/media/Editorial/lamellenklaerer/unten_liegende_haltekonstruktion.png)