Trickling filter technology

The trickling filter technology is one of the oldest technologies for biological wastewater treatment and has undergone some significant developments since it’s early days. Nowadays it’s considered an easy-to-operate and almost maintenance-free technology with low power demand. The only power requirement goes for pumping, there is no need for power-hungry blowers, since the aeration is provided by natural draft.

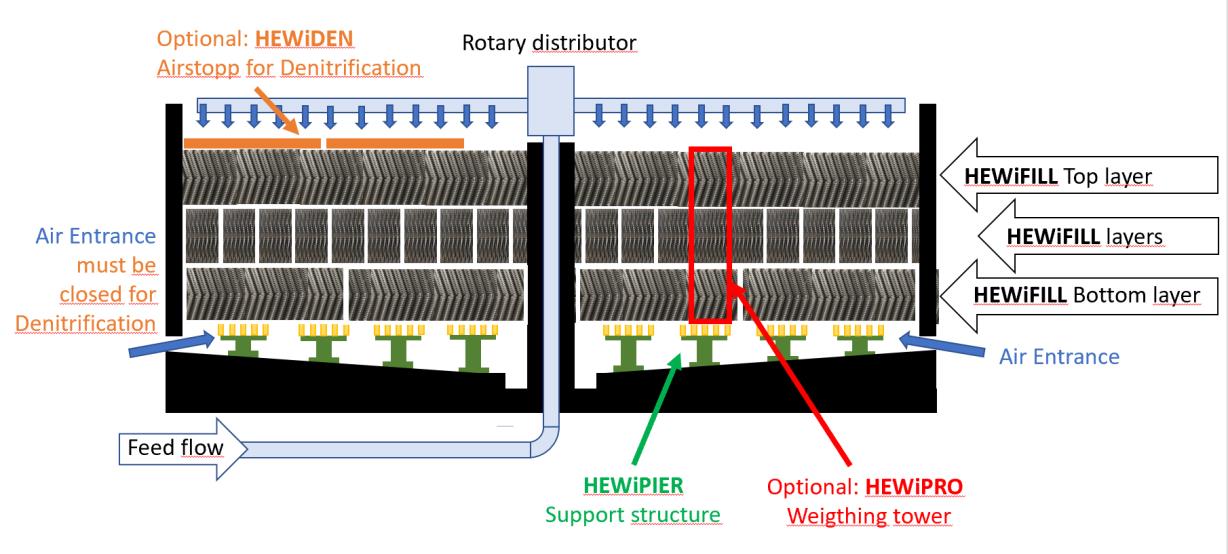

The core of a trickling filter is a fixed bed biological reactor that operates under mostly aerobic conditions. Pre-settled wastewater is continuously and evenly distributed on top of the filter-media.

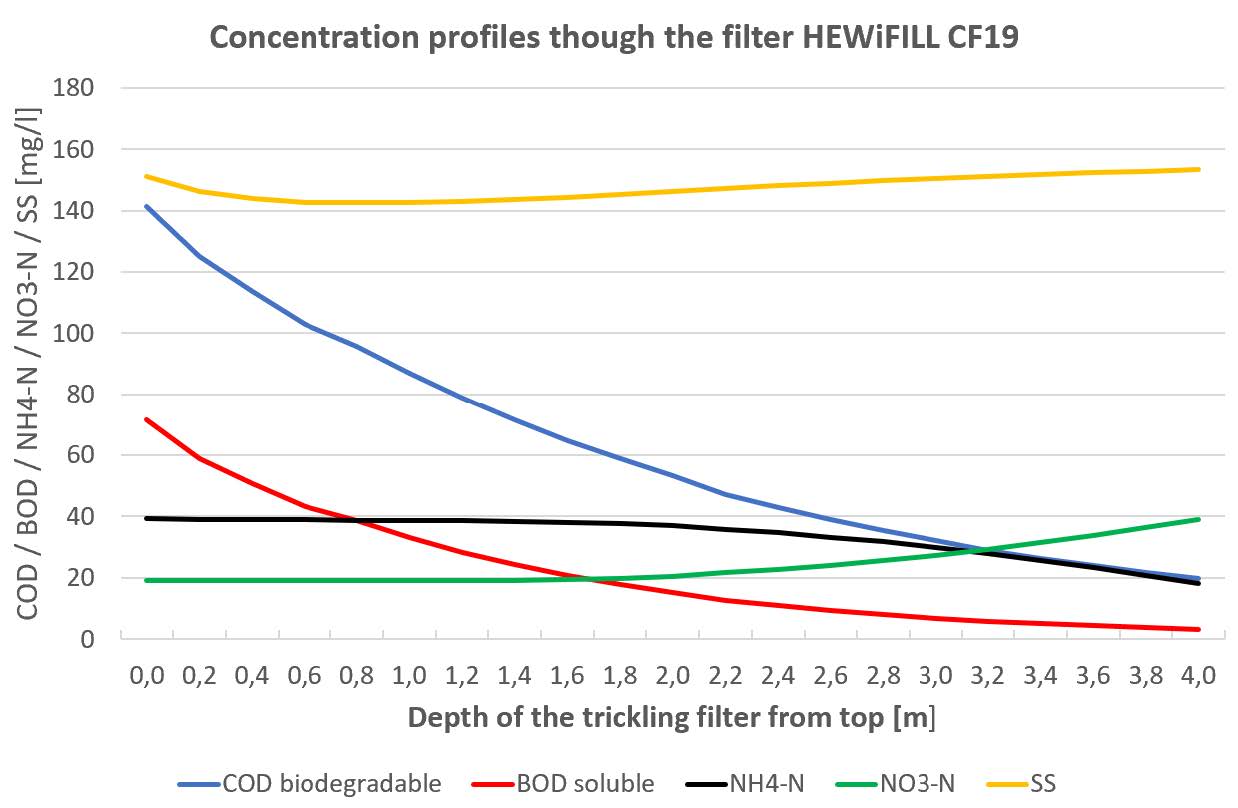

Organic and biodegradable inorganic wastewater components are degraded by a biofilm covering the surface of the media.

Thus, the key component of a modern trickling filter is the structured media packing that provides a large surface for biofilm and sufficient ventilation while the water migrates through the filter.

HEWITECH trickling filter media can be used in any trickling filter, from high loaded roughing filters to predominantly nitrifying filters.

HEWiTECH trickling filters are used wordwide and contribute to the protection of water resources and the environment

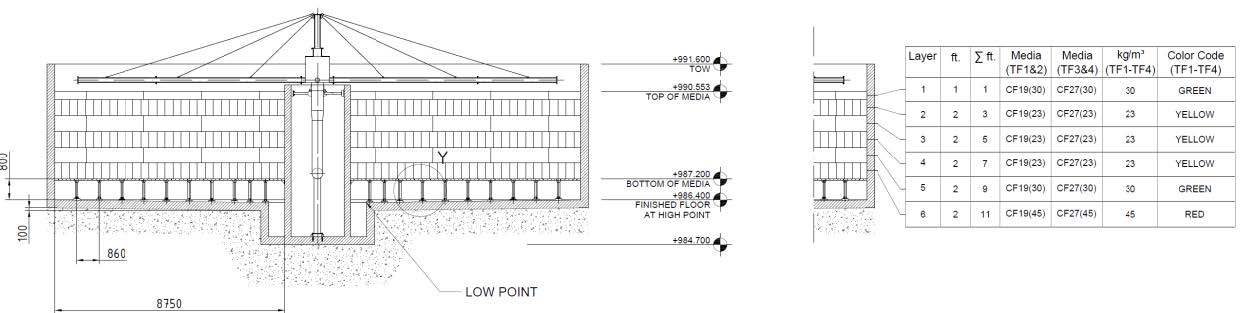

A trickling filter is typically a circular tower with a media height of 3m – 5m and a diameter of 10m to 35m. Heights up to 12m and diameters up to 50m are also realized, but don’t represent typical sizes.

Most of the tower volume is filled with the filter media, which is preferably made of thermoformed Polypropylene sheets. PVC fill media was used in the past, but it’s getting less important and it’s considered less environmental friendly. PVC cannot disposed easily at the end of its lifetime.

The media sits on a underdrain structure holding the load from the media and it’s biofilm/water content. The underdrain structure must allow ventilation and must allow the water to leave the filter media. Typically, the underdrain support is 300mm to 600mm above the trickling filter floor.

The filter floor is sloped by 1%-2% in order to drain the effluent and send it toward a collection channel in the center or along the perimeter of floor.

The trickling filter feed is applied by a rotary distributor, that distributes the feed flow evenly on top over the open surface. Most distributors are hydraulically driven by the outflowing water, some distributors have a motor-drive, which allows a more controlled rotation speed.

Trickling filter media needs to be placed on a proper base.

The support structure needs to meet structural requirements and must be suitable to fulfill process requirement with regard to air supply and blockage prevention.

The support structure HEWiPIER fulfills the requirements addressed to support structure:

- It can be adapted to any design weight. Typical design weights range from 1000 kg/m2 of floor area for shallow load loaded filters up to 8000 kg/m2 of floor area for tall high loaded filters.

- It stanchion parts have an integrated slope compensation, hence the piers are installed vertically on a sloped floor (compensation up to 8% or 4.5 Deg)

- The piers consists of long-lasting PVC pipes with base and head plates. The support grating is made of rigid fiberglass beams with > 50% glass content

- HEWiTECH provides the structural design and installation instructions and installation drawings

- all components are easy and fast to install and the pieces fit together.

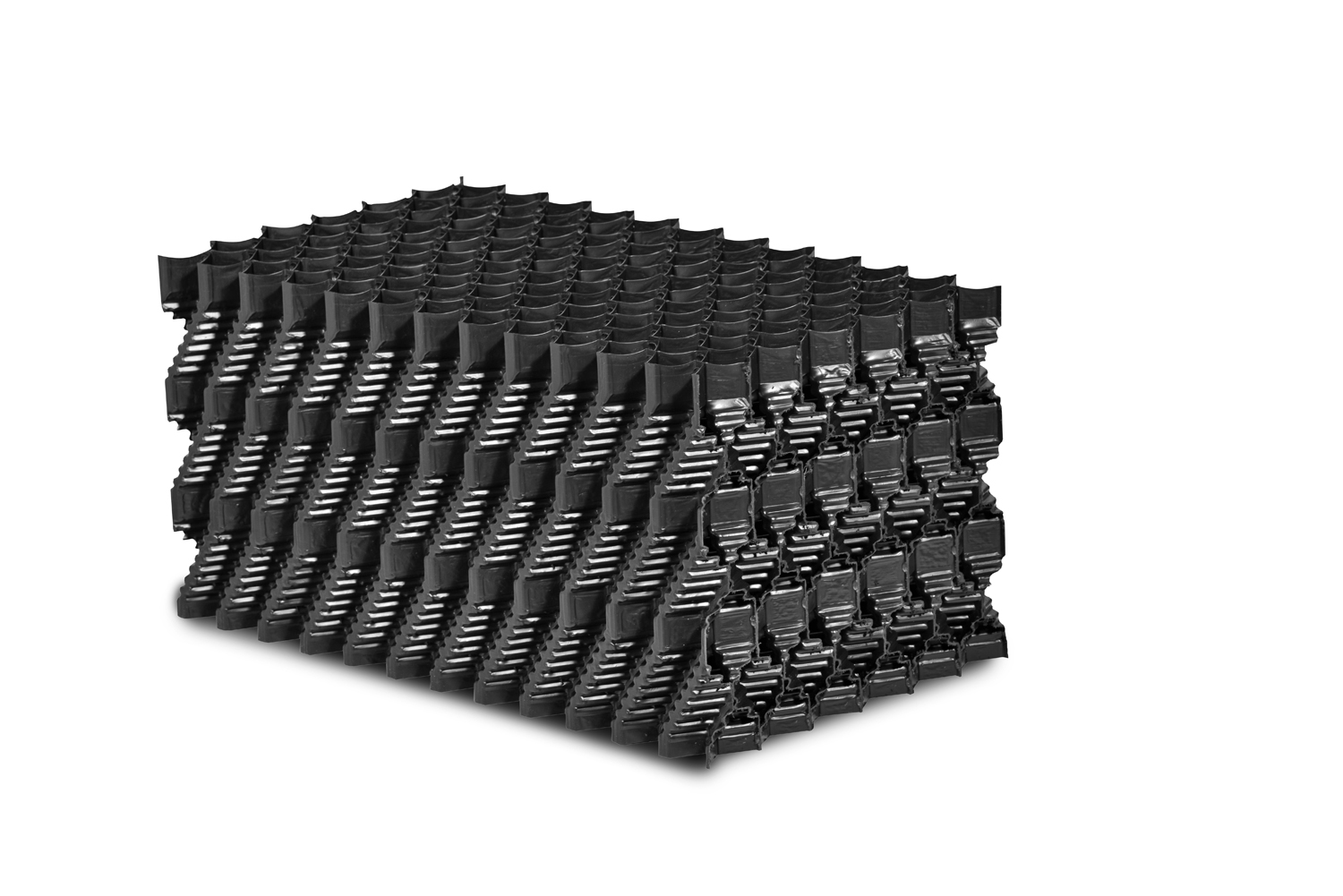

HEWiFILL CF19 and CF27 media is probably the most common trickling filter media for municipal wastewater, with typically low to medium loaded systems

The media has a 60 deg crossflow-arrangement for optimized distribution of the water. Small sub-corrugation increase the specific surface and slow down the trickle-flow for an intense contact of water to biofilm coupled with an optimized biodegration of organic compounds (BOD ; COD)

HEWiFILL CF19 is the right choice, when a high BOD removal with (partial) nitrification is the treatment aim. It’s flute size is 19mm, the specific surface counts 150 m2/m3

HEWiFILL CF27 is the right choice, if nitrification is considered of less importance, but the BOD shall be eliminated to a large extend. Due to the large flute size of 27mm, it is less sensitive against larger particles.

The specific surface is slightly less than HEWiFILL CF19, but still 125 m2/m3

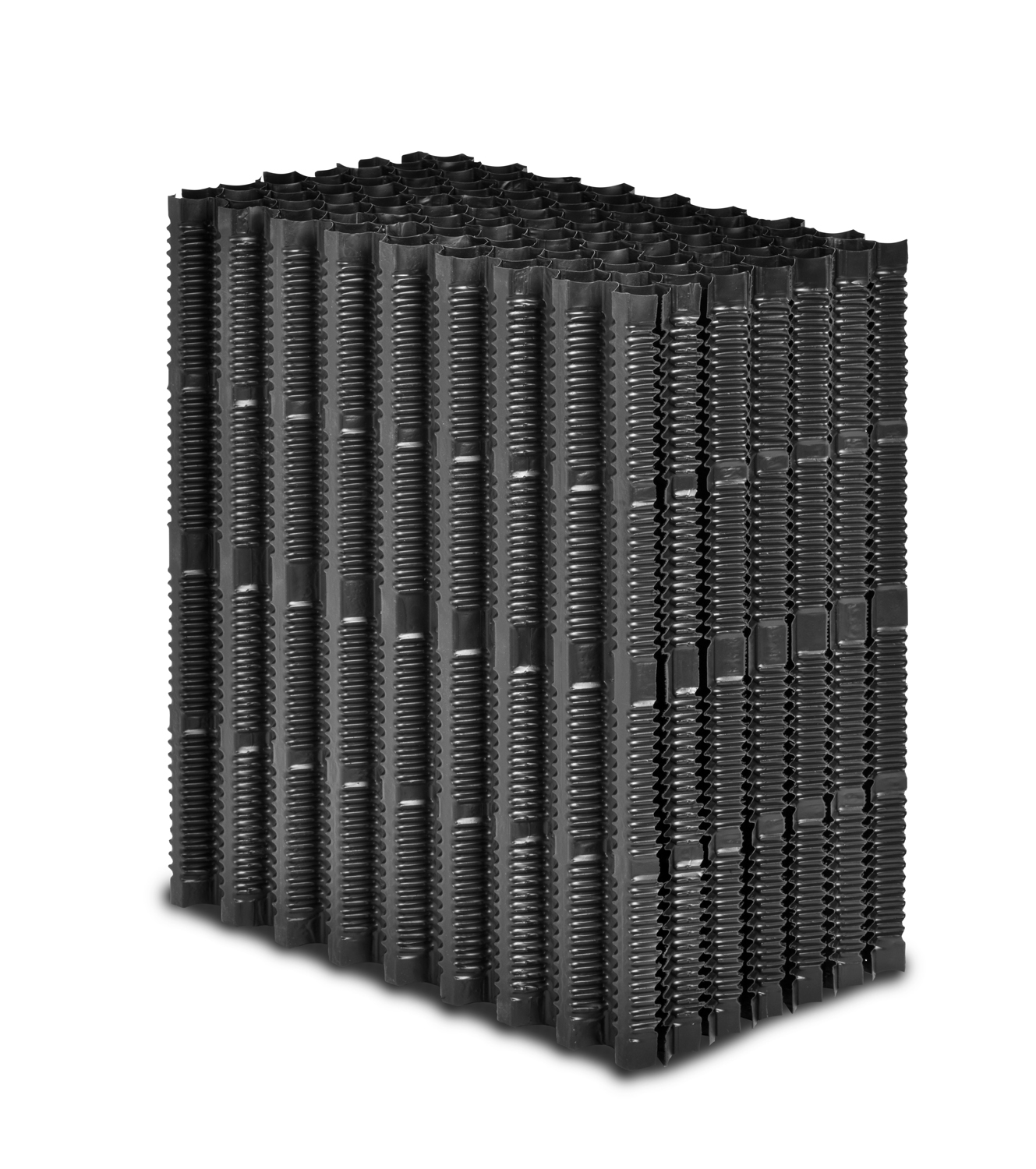

HEWiFILL CF12 is designed for high rate nitrification at a low simultaneous BOD loading rate.

Nitrifying biofilms are typically thin, therefore the HEWiFILL CF12 media has a flute of 12mm and provides a large specific surface of 240 m2/m3 with a corresponding high rate nitrification.

The flutes are cross corrugated with sub-corrugation for an enhanced contact time with the nitrifying biofilm.

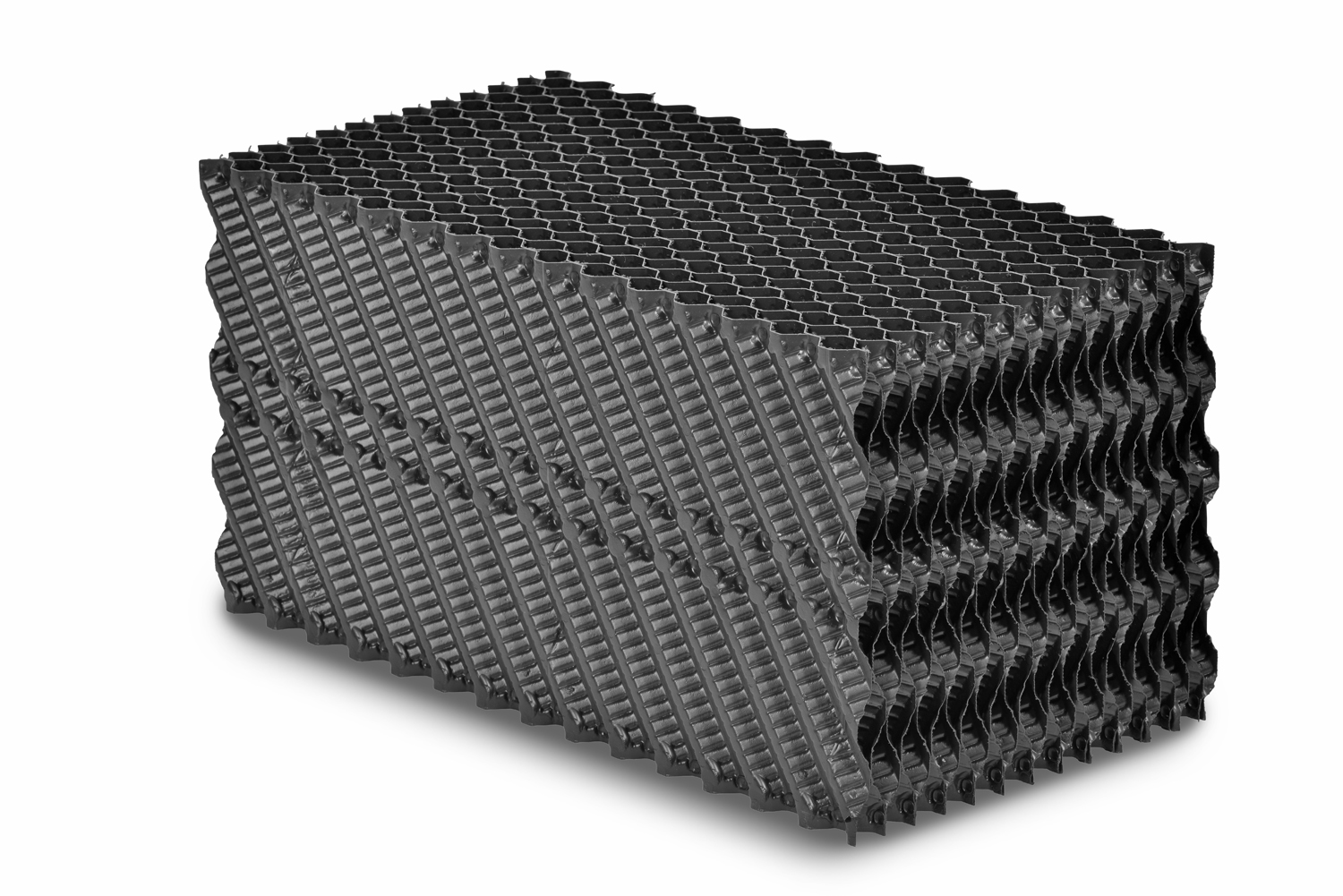

HEWiFILL VF23 is designed for high rate filters, where a high BOD turnover per unit volume is required. The biofilm can growth thick at high BOD loads and desludging needs to be considered.

Therefore the HEWiFILL VF23 consists of vertical channels in an honeycomb arrangement. There is sub-corrugations slowing down the waterflow, but detached sludge and larger particles can be flushed out easily due to the vertical arrangement. The channel diameter is ~ 40mm with a specific surface of 125 m2/m3.

HEWiFILL VF23 is the right choice for high rate municipal applications and a range of industrial applications with uneasy sludges, for example filamentous sludge in pulp and paper.

HEWiFILL VF50 provide the highest safety against clogging. It’s a vertical channel type media with almost no sub-corrugations. Its designed for extremely high loaded systems with a high particle load.

HEWiFILL VF50 can be used as a pretreatment for activated sludge, where the MLSS content is passed through the media.

Its typically not used for full treatment, but for a rapid partial BOD removal with a high reduction per reactor volume followed by a downstream treatment of the remaining BOD.

The HEWiFILL VF50 media has 50mm diameter channels with a smooth surface. The specific surface is ~ 100 m2/m3

The media has a splash-kink in the middle, that prevents a droplet from passing the media without touching the biofilm covered wall.

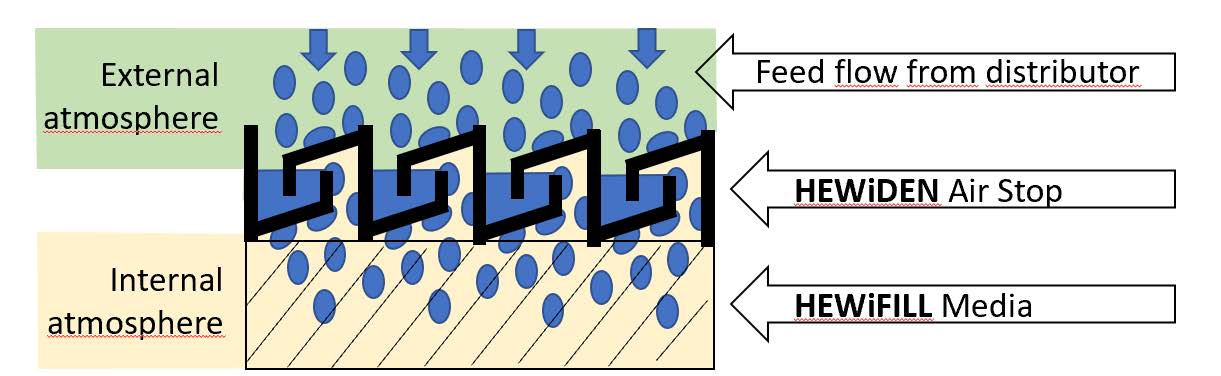

Cover for Denitrification: HEWiDEN air stop

With the HEWiDEN air stop an aerobic trickling filter can be converted into an anoxic denitrifying filter as it prevents the air circulation over the surface.

The HEWiDEN air stop is placed as 100mm thick a top layer and allows the water from the rotary distributor to pass without resistance, it can even carry particles up to 15mm.

The filter can be flushed without restrictions and the SK value is fully transferred towards the below media.

However, air flow is completely stopped with a HEWiDEN air stop.

The HEWiDEN air stop is a perfect alternative to large gas-tight dome-structures covering the entire upper part of the filter.

The HEWiDEN air stop is walkable and the operator has access to the distributor without being exposed to an oxygen-free environment.

Monitored: HEWiPRO – weighting towers

The operating of a trickling filter is accompanied by a constant growth of biomass and a constant detachment and release of biofilm.

In well balanced trickling filters both aspects compensate themselves, leaving a vital biofilm of uniform thickness, that covers the media surface.

The HEWiPRO weighting tower is designed to monitor the average weight of a representative section of fill media, typically a tower of 60x60cm2 with a height equal to the media height in the filter.

The representative fill-media is enclosed in steel frame and located on a load cell.

The weight development allows the operator to react on an increase or decrease of the captured biomass by adjusting the rotary speed and the flushing intensity.

A sound trickling filter design requires a process calculation, that results into the actual sizing of the filter and the selection of an appropriate trickling filter media.

The structural requirements are determined with a subsequent second design step. It results into the support structure design and the trickling filter media structural strength requirements.

Process design

The process design of trickling filters has been subject of scientific studies for a long period. Several models have been proposed , most of them can be considered as modified models from earlier versions.

The most recent model* for trickling filter design has been published in October 2016 by the DWA (German wastewater association), where several full scale operational results were used for verification – most of them coming from trickling filters with plastic media similar to HEWiFILL.

The project aim was to combine and verify a carbon (BOD , COD) elimination model and a nitrification model and to get a more accurate tool to gauge the temperature impact.

In opposite to earlier models , such as the Velz-Equation, the DWA model is not easy to handle and its application requires several re-occuring iteration steps.

For trickling filter projects we offer a free-of-cost doublecheck based on the DWA model, either on an existing design or we can propose a trickling filter sizing and media selection based on customer requirements.

Structural design

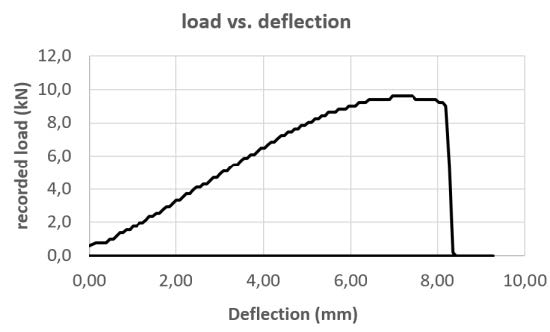

The structural design of the support and the media-layer-system is of utmost importance for the long term service of the filter. Biofilm attachment and percolating water within the media cause a high operational load several times more than the media weight itself.

The maximum operational weight can be determined for the bottom layer due to the cumulated weight of the layers above.

The design operational weight can be determined in accordance with German DIN 19557-T2 or is otherwise specified by the customer. In most cases the design weight ranges from 450 kg to 650 kg per-Meter-Cube of media.

HEWiFILL media can be produced to withstand any load due to the variation of the sheet thickness.

Finally we always propose a cost-optimised layer structure.

Our design includes special aspects of the top layer (UV radiation and foot traffic) and of the bottom layer (load transfer to the support structure)

We determine the load bearing capacity of our media in-house with own modern test-machines and high quality standards.

Our structural layer design considers material-specific aspects, the design life-time and temperature impact.

What is better, PP or PVC?

From the process point both materials perform equal. PVC material has been used in earlier times as the sole material since solvent bonding cannot be applied to PP.

Nowadays this restriction has been overcome by the PP thermal welding technology, hence the advantages of PP can be utilized: PP is more robust and less brittle than PVC. Furtheron, PP has a more green life-cycle.

Production workers can assemble the media in a solvent free workshop.

Is on-site assembly possible?

The assembled media contains more than 95% void air, thus shipping can be cost intensive issue.

HEWiTECH delivers corrugated sheets along with a welding machine directly to the customer for on site assembly. The customer also benefits from lower labor cost at the construction site.